How Precious Metal Recycling Companies Tackle Water Usage

Comprehensive Guide to Eco-Friendly Precious Metal Recovery

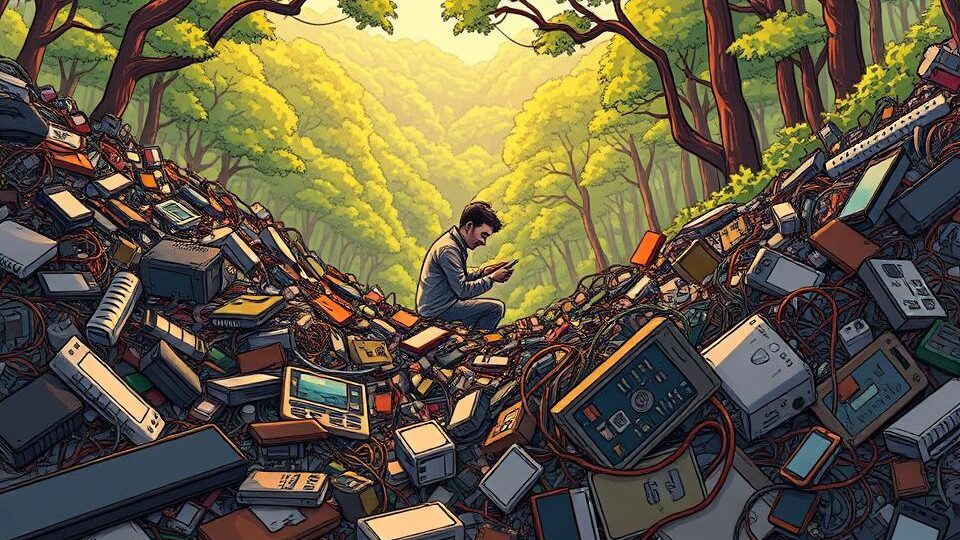

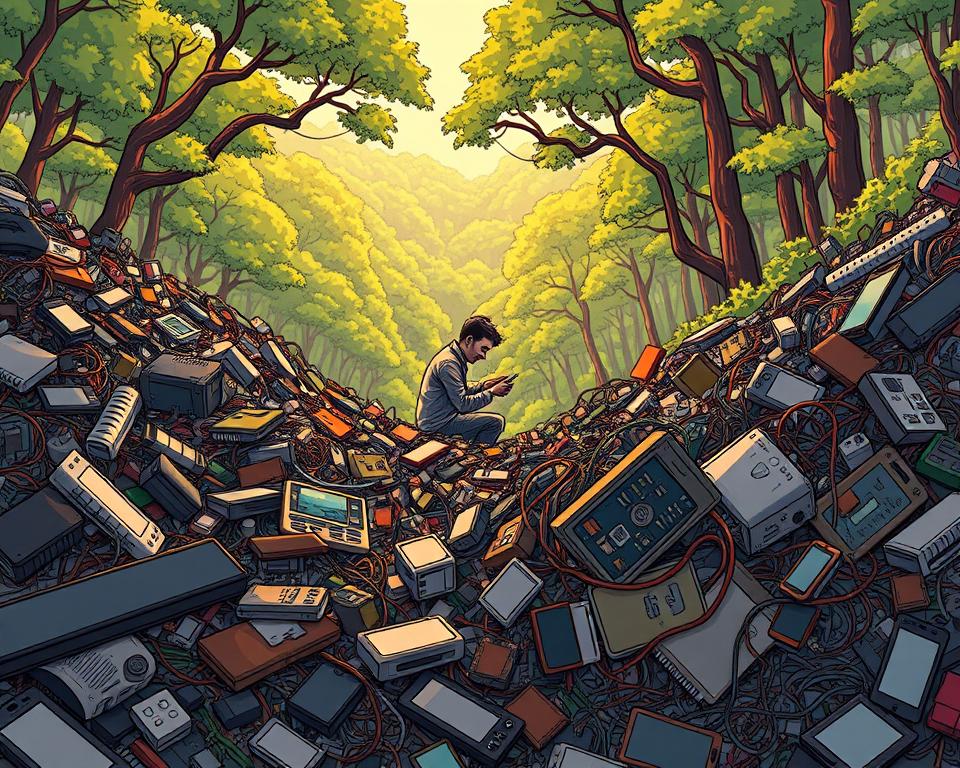

More than $60 billion in precious metals end up in e-waste every year—did you realize that? Such a massive amount highlights why precious metal recycling is so vital. Recycling these metals benefits both the economy and the planet. By recycling metals like gold, silver, platinum, and palladium, we cut down on pollution and save natural resources.

Leaders such as Dongsheng Metal Trading are paving the way for sustainable recycling. They ensure these valuable metals are reused, not dumped in landfills. Such a precious metal recycling companies model drives eco-friendly recycling and sustainable methods.

Major Highlights

- Over $60 billion in precious metals is disposed of in electronic waste annually.

- Precious metal recycling reduces environmental impact and conserves resources.

- Valuable metals include gold, silver, platinum, and palladium.

- Green recycling methods are essential for a sustainable future.

- Recycling experts like Dongsheng Metal Trading lead the industry.

Exploring Precious Metals and Their Worth

Naturally scarce metallic elements called precious metals draw interest from industries and investors. Gold, silver, platinum, and palladium are prime examples, known for their unique properties. They offer conductivity, resist corrosion, and occur in limited supply. Extracting and refining them uses up huge resources, so recycling becomes critical.

Market demand and each metal’s properties drive its value. Metal recycling ensures the supply chain remains robust. It cuts the environmental toll of mining operations. Advanced recycling can bring metals back to their initial quality. This preserves finite resources while yielding economic benefits.

Defining Precious Metals

Unique features make precious metals ideal for many uses. Their rarity and intrinsic properties are foundational to their economic significance. Key examples include:

- Gold: Prized for its shine and tarnish-proof nature.

- Ag: Celebrated for its adaptability and conductivity.

- Pt: Celebrated for its durability and catalytic properties.

- Palladium: Increasingly popular in automotive and electronic applications.

Benefits of Precious Metal Recycling

Recycling these metals is now key to sustainable practices. It saves scarce materials and sharply cuts mining’s eco-footprint. Here are some benefits:

- Lessening of habitat destruction from mining.

- Lower energy consumption compared to extracting new metals from the earth.

- Supporting a circular economy via material reuse.

- Potential for financial gains through the reclaiming of high-value materials.

Why Precious Metal Recycling Matters

Recovering metals delivers big eco and financial wins. Pointing out these perks shows how to shrink our eco-impact. It also drives economic growth and stability.

Green Benefits

The environmental benefits of recycling precious metals are significant. By reclaiming metals from discarded electronics and industrial scrap, we cut down on landfill waste. That cuts new mining needs and saves resources.

It lessens mining impacts, including ecosystem harm and contaminants. A focus on metal recovery moves us toward real sustainability.

Economic Advantages

Financial perks of recycling are just as strong. Recycling precious metals can lower manufacturing costs. It lets businesses choose reclaimed over freshly mined metals.

It spawns jobs in recovery plants and steadies markets as recycled-metal demand rises. Harnessing these gains helps firms improve their bottom line. They also contribute to a greener economy.

Steps in Metal Recycling

The precious metal recycling process is complex, involving several stages to ensure maximum efficiency. Collection of e-waste, jewelry, and industrial scrap kicks off the process. They are sorted, decontaminated, and analyzed to gauge composition and value.

Recovery Steps

This systematic approach is vital for effective metal recovery. All stages focus on boosting metal yield. Sorting separates metals by type and purity. Decontamination eliminates residues that block recovery. Chemical analysis pinpoints metal levels to drive technique decisions.

Recycling Techniques Used

Advanced recycling techniques are employed to achieve high metal recovery rates. Thermal reduction, using high temperatures to separate metals from ores, is a key method. Melting refines and aggregates metals, while wet chemical processes are used for delicate separations. Recyclers like Dongsheng Metal Trading employ these approaches to improve yields and returns.

Recyclable Precious Metals

Recovery efforts support both ecology and resource reclamation. Numerous precious metals lend themselves to recycling, serving both business and environment. Awareness of recyclable metals guides consumers and companies.

Key Precious Metals

Familiar precious metals include gold, silver, and platinum. They’re found in jewelry, coins, and industrial uses. Gold’s high price and use make it a prime recycling target. Silver’s role in cameras, electronics, and solar energy makes its recycling vital.

Platinum, while rarer, finds value in catalytic converters.

E-Waste Metals

Electronics scrap contains metals ripe for recovery. Devices such as phones and computers hold palladium and indium. Reclaiming them cuts e-waste and recovers key resources.

It’s crucial to recover these electronic metals. Industries aim to minimize waste and efficiently recycle resources.

Industry Benefits of Precious Metal Recovery

Recycling precious metals supports industries by providing efficient, green resource supply. The electronics industry, with its frequent use of precious metals in devices, benefits greatly. The aerospace and medical fields use precious metals in essential applications. Exploring how these industries recycle precious metals reveals the environmental and economic benefits.

Electronics Industry

Electronics spearheads recovery, given the metal content in phones and PCs. Quick device turnover spawns more electronic scrap. Thus, recycling gold, silver, and palladium efficiently becomes vital. It preserves nature and lowers mining-driven CO₂ emissions.

Businesses enhance recovery to align with green and zero-waste aims. Such a move upholds efforts to conserve and protect.

Aerospace & Medical

Metal recovery is key in aerospace and medical sectors where metals are in vital parts. Alloys prized for strength and anti-corrosion make up flight and medical components. Recycling these metals can significantly lower material costs and comply with environmental regulations.

They recognize that recycling offsets material scarcity. It also enhances operational efficiency, making recycling a key strategy for sustainability.

Selecting Recycling Partners

Finding trustworthy precious metal recycling companies is key to recycling effectively. It’s wise to ask important questions to understand their operations. Pricing models and processes make a big difference. By comparing services, you can see what each company offers and make a smart choice.

Key Questions for Recyclers

- Can you share your precious-metal recovery accreditations?

- Can you explain your processing methods for different metals?

- Which recovery percentages do you achieve for each metal?

- How do you handle pricing, and what additional fees might apply?

- Do you have client testimonials or references?

Evaluating Offers

When searching for a recycler, it’s vital to compare different companies based on their services. Create a table to compare key factors such as:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

Side-by-side comparisons help pinpoint the ideal recycler. That way, you maximize returns and maintain quality.

Recycling Precious Metals: A Green Guide

Knowing recycler operations matters if you recycle metals. They oversee everything from scrap pickup to refining. That approach drives top efficiency and returns.

Behind the Scenes of Recycling

Recyclers use advanced methods for metal recycling, including testing, separation, and refining. They start by collecting metal scraps from various sources. Next, they employ precise methods to sort metals. Next, they refine these metals to extract precious elements like gold, silver, and platinum.

That workflow both boosts recovery and promotes green methods. It’s essential for long-term sustainability.

Selecting Your Ideal Recycler

When picking a recycler, several factors are important. First, look at their environmental practices. In today’s market, a commitment to sustainability is essential. Also, consider the services they offer, from basic collection to full processing.

Cost is equally important. Gather price quotes for side-by-side comparisons. Firms such as Dongsheng Metal Trading tailor services to each sector. They remain a trusted partner for targeted recovery.

The Role of Metal Recycling Facilities

Metal recycling is a critical sector for sustainable practices and waste management. Multiple types of facilities handle various recycling demands. Awareness of facility types guides you to proper recyclers. It aids companies and conserves nature.

Recycling Center Types

Facilities differ greatly in their focus and processes. Some yards recover gold and silver; others accept all metal waste. Here are a few common types:

- Metal Scrap Yards: Typically focus on general metal waste, including ferrous and non-ferrous metals.

- High-value metal recyclers provide precision recovery for gold, silver, platinum, etc.

- E-Waste Recycling Centers: Specialize in recovering metals from discarded electronics, capitalizing on the valuable components often found in these devices.

Facility Access Factors

Easy access to facilities boosts recovery efficiency. Businesses must consider the logistics of transporting materials. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Distance | Facilities located nearer to businesses minimize transportation costs and time. |

| Partnerships | Connections with nearby facilities speed up recycling. |

| Services Offered | Awareness of service menus aids in picking the right center. |

In sum, selecting the right type of recycling center and ensuring convenient access can significantly enhance the efficiency of metal recycling operations.

Electronic Waste Recycling and Precious Metals

Discarded electronics threaten the environment. Many e-waste items hold recoverable precious metals. This highlights the importance of seeing e-waste as a valuable resource.

Metals in Devices

Many electronic devices hold small amounts of precious metals like gold, silver, and palladium. You’ll find them in components such as:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

Common electronics conceal recoverable metals. By recycling, we retrieve and reuse these valuable elements.

E-Waste Recovery Benefits

E-waste recycling is vital for both environmental protection and resource recovery. It trims dump loads and conserves raw materials. The benefits of recycling e-waste metals are clear:

- It minimizes environmental risks from improper disposal

- It curbs carbon footprints with sustainable recycling

- It bolsters circular models by returning scrap to production

Championing electronics recycling fosters responsible resource use. It secures a healthier planet for tomorrow’s children.

What’s Next in Metal Recycling?

Recycling is changing fast thanks to new tech and eco-driven demand. With resource conservation rising, recyclers are innovating. Adopting fresh techniques, they’re shaping tomorrow’s recycling.

Green Recycling Trends

Modern green recycling strives to cut waste and eco-damage. Companies are shifting towards eco-friendly practices, like using biodegradable packaging and energy-efficient processes. Such moves match worldwide green goals and nudge industries to be more eco-responsible.

New Metal Recovery Tech

Advances in recovery techniques are key to improving precious metal recycling efficiency. Automated sorters and hydrometallurgy ramp up yield. They boost recovery and cut environmental costs—a leap for metal recycling.

Starting a Precious Metal Recycling Venture

Starting a precious metal recycling business demands meticulous planning and a deep grasp of operational and market dynamics. Leaders should map out steps, secure compliance, and set firm roots. This includes conducting extensive market research and identifying target clients. Also, obtaining necessary permits and understanding legal aspects is vital for sustained success.

Launching Steps

To launch your recycling venture, follow these steps:

- Conduct market research to understand needs and rivals.

- Draft a strategy blueprint covering targets and methods.

- Acquire suitable recycling equipment that meets your operational needs.

- Obtain capital via loans or investors.

- Get all required permits and licenses.

- Implement a marketing strategy to draw in customers.

Compliance and Certifications

Knowing regulatory requirements is vital for a recycling startup. Complying with eco-regulations keeps your business green and lawful. Key considerations include:

- Getting licensed by appropriate agencies.

- Ensuring full compliance with disposal and recycling laws.

- Ensuring all employees are trained on safety protocols and procedures.

In Summary

Recovering precious metals conserves resources and protects our planet. It helps people and companies cut waste’s ecological toll. That reclaimed metal cuts mining demand and spawns recycling jobs.

Metal recovery delivers both eco and economic upsides. Working with Dongsheng Metal Trading guarantees green standards. That partnership bolsters circular models for recyclers and buyers alike.

The journey to a sustainable future depends on collective action in recycling precious metals. Raising awareness fosters mindful use and eco stewardship. Implementing these measures supports us today and safeguards future generations.